The main rule to solve a problem , ofter valid in other field , is to follow a line from INPUT to CONTROLLER and finally the OUTPUT .

In our case the INPUT is the sensor , the CONTROLLER is the strategy and the OUTPUT can be checked on data acquistion .

Sensor Setup ( the INPUT )

To setup correctly the Gear Shift some simple checks should be made .

First of all the Load Cell Sensor should be checked :

- Configure the Load Cell sensor ( menu calibration /load cell force )

- Set the Offset to the same value You read on Load Cell Analog channel

- Set the Gain to the value You can read on Your sensor datasheet ( usually 500 N/Volt ) , set the sign ( + or – ) to obtain a positive value on Load Cell Force channel applying a force to increase gear ( 1->2->3 and so on … )

Strategy Setup ( the CONTROLLER )

For Gear Shift Up :

- Enable the gearshift from Working Modes ( menu Rider Setting / Workmode Setting )

- Setup the basic features only ( menu Gear Shift / Gear Shift Up Enable )

- All Options = OFF

- Debounce Time = 200 mSec

- ReArm Force = 150 N

- Trigger Force = 250 N

- Min GAS = 20 %

- Min SPEED = 0 km/h

- Setup the CUTS ( menu Gear Shift / Gear Shift Up Cuts )

- TDC Loop Size = 10

- For All gear ( included default ) Set Cut Timeout = 70

- Switch OFF both IGNITION and INJECTION ( menu Gear Shift / Gear Shift Up Cuts )

- Set INJECTION Pattern #1 = 00000000

- Set IGNITION Pattern #1 = 00000000

For Gear Shift Down :

- Enable the gearshift from Working Modes ( menu Rider Setting / Workmode Setting )

- Setup the basic features only ( menu Gear Shift / Gear Shift Down Enable )

- All Options = OFF

- Debounce Time = 200 mSec

- ReArm Force = -150 N

- Trigger Force = -250 N

- Max GAS = 10%

- Min SPEED = 0 km/h

- Setup the BLIP ( menu Gear Shift / Gear Shift Down Blip )

- For All gear ( included default ) Set Cut Timeout = 200

- Setup the whole table for Target TPS = 20 %

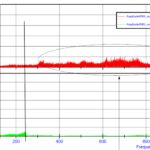

Data acquistion check ( the OUTPUT )

After setting up everithing here above , You can check what happens on data acquistion . You could setup Your data analyzer with following channels :

- RPM , TPS , SPEED

- LOADCELL , GEAR_POS

- CUT_LEVEL , CUT_FUNCTION , STR_FUNCTION

- GEARSHIFT_UP_SM , GEARSHIFT_DN_SM

It would be perfect if You can show STR_FUNCTION using a BIT MASK instruments ( You could check Your data analyzer functionality ) . Check the Supersport Channels Explained post for more details .

Now You can check if all “chain” work like should .

So when rider press pedal ( LOADCELL ) value pass the TRIGGER THRESHOLD , then the STR_FUNCTION must signal the GEAR SHIFT strategy active , and CUT_LEVEL must be 100 % ( for GearShift Up ) , and TPS move up ( for GearShift Down ) .

If something don’t happens like expected , made some step back and check Your configuration .

For a detailed description We advise to read carefully following documents :