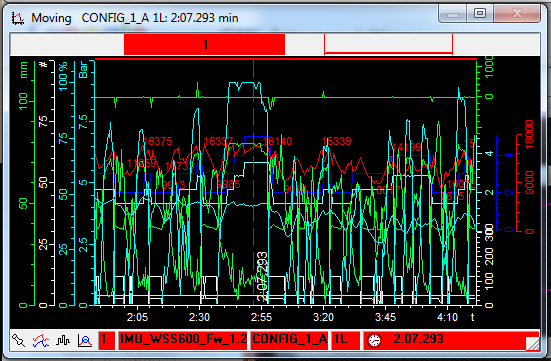

The motorbike supersport applications , both 300 and 600 , share same CAN protocol . This protocol is public ( You can download it from link on bottom of the page ) , and many third parts dataloggers support it ( ask to Your supplier if He does ) . Following informations can be user for MKE5-WSS300_A and MKE7-WSS600_A models ( how to check the ECU model ) .

Main Engine channels

RPM : this is the most used and know channel , it’s the engine speed , nothing to say bout it .

TPS : throttle position , his unit of measure is % , usually the range is from 0 to 100% , but sometimes it can have values over 100% and under 0% , that the reason why the channel should be set like SIGNED .

GAS : it’s the rider GRIP position , for motorbikes without Ride By Wire , the value is egual to TPS . GAS have same characteristics of TPS channel above .

DEMAND : this channel , on motorbike with Ride By Wire , is the output of DEMAND tables You can setup on Your strategies calibration . For bike with hard wired TPS , the value is same as TPS and GAS . DEMAND have same characteristics of TPS channel above .

WTS : channel for water ( engine ) temperature . Nothing to say bout it .

ATS : channel for air temperature . Nothing to say bout it .

Other Engine related channels

BAP : barometric air pressure . Sensor can be installed inside airbox too . On some applications this can be evaluated from MAP sensor too , in case the BAP sensor is not present .

MAP : manifold air pressure , it’s read under the throttle plate , so the value is often under the BAP value . On many application it’s used for engine sysncronization too . Fuel injection , to be more accurate , can be defined to use it for first part of TPS opening position .

OPS : the oil pressure is used for engine diagnostic , and ( if enabled ) to switch off the engine through DROP OFF strategy .

FPS : the fuel pressure is not used by engine calibration and strategies , it’s inserted for diagnostic only .

OTS : the oil temperature is not used by engine calibration and strategies , it’s inserted for diagnostic only .

Lambda related channels

LAMBDA : the lambda channel came directly from internal lambda controller for Wide Band sensor . For correct lambda value , the LAMBDA_TEMP should be always from 800 to 900 Celsius . Lambda closed loop is automatically disabled in case of sensor fails .

LAMBDA_TEMP : here you can know the lambda sensor temperature ( internal ) , the ECU try to keep it at 830 Celsius , lambda value could be inconsistent under 800 Celsius and over 900 Celsius .

LAMBDA_FLAGS : value that describe what is the actual state of lambda closed loop startegy . In case INJ_CORR_LAMBDA is always 1 , and You expecting an active correction , first of all You should check this channel . Take a look to details on document on bottom of this page for more details .

INJ_CORR_LAMBDA : this channel show the actual gain factor for lambda closed loop strategy . This is correction factor , so values over 1 means that strategy is giving more fuel , under 1 is reducing fuel .

Vehicle related channels

SPEED_FRONT , SPEED_REAR : front and rear speed caming from wheel speed sensors , and adjusted with tyre profile . For that reason it’s important that IMU calibration is done .

SPEED_VEHICLE : the speed of vehicle ( motrbike in Your case ) is evaluated by ECU from different sources . It’s used by many strategies ( e.g. Speed limiter ) it can be evaluated also without speed sensors , from RPM and GEAR_POS .

GEAR_POS : it’s the actual gear position . If you have a sensor for engadged gear , it’s used ( if it works ) . On all other cases the ECU will try to calculate by itself using RPM and SPEED signals . On that last cases , value is correct only when clutch is closed .

GEARPOS_VOLT : this value is the volta of gear position sensor . It’s very usefull for diagnostics poupose , and for a fine calibration of sensor ranges for each gear .

LOADCELL : the channel unit of measure is NEWTON . In case You are using a force sensor ( load cell ) it’s really , because of this measure a force .

TRANSMISSION_RATIO : this channel contains the value for actual transmission ration from engine crakshaft to real wheel . It’s usefull like base for Your math channels .

Engine Brake related channels

VIRTUAL_RPM : this is evaluated by ECU to have a good reference on Engine Brake setting . In short , it’s evaluated from TRANSMISSION_RATIO and FRONT_SPEED . Check the engine brake strategy user manual for details .

CLUTCH_SLIP : this one of most important channels for engine brake setting . Ranges start from -100 % to 100 % , 0 % means no slip .

TORQUE_REAR : this channel is very impornat for engine brake setting too . Tho have this channel working the ENGINE TORQUE table should be compiled , with negative torquel values too ( hi RPM and low TPS ) . This is the torque applyed to rear wheel .

Vehicle dynamics channels

SUSP_FRONT : value for front suspension stroke , linearization and zero of this sensor is managed by ECU .

SUSP_REAR : value for rear suspension stroke , linearization and zero of this sensor is managed by ECU .

BRAKE_FRONT : value for front brake pressure , linearization and zero of this sensor is managed by ECU .

BRAKE_REAR : value for rear brake pressure , linearization and zero of this sensor is managed by ECU .

BIKE_LEAN_ANGLE : this is the lean angle of the bike , it’s estimated from buildin IMU inside ECU . This is an estimation that can be effected negatively by excessive vibration and wrong ZERO of IMU .

BIKE_VERT_ACC : this value show the vertical acceleration . It’s used like main channel from DROP OFF strategy ( bike fall down detect ) . This measure can be effected negatively by excessive vibration and wrong ZERO of IMU . You should check first of all that values on the straigth not go under 5-6 m/sec2 .

Engine Cut channels

GEARSHIFT_UP_SM : this channel describe what the actual state for Gear Shift UP strategy , take a look to Gears Sjfit startegy for details .

GEARSHIFT_UP_DN: this channel describe what the actual state for Gear Shift DOWN ( blipper ) strategy , take a look to Gears Sjfit startegy for details

CUT_LEVEL : this is one of Your “best friend” channel . Looking to this channel You can know how much the ECU would like to cut power . In case You have some miss-firing You must always check this channel for first , to know if it’s something that “ECU want” or not . Range is from 0% to 100 % .

CUT_FUNCTION : this is the “other friend” channel . In case CUT_LEVEL is more than 0 % , this describe to You what is the strategy that is cutting . Take a look to CAN protocol details ( file on bottom of the page ) for details .

Rider channels

SHIFT_LIGHT : if You configure the Dashboard Gear Shift light over this channel ( instead of RPM ) You can have big benefits , because in this way You can set it from ECU , for GEAR_POS and with TPS filter . It’s value is from 0 to 100 % .

WORKMODE : this is the actual working mode ( map ) in use .

WORKMODE_MASK : this channel contains the bitmask for You actual WORKMODE . If You can show a bit mask related to this channel on Your data analizer software , this will be very usefull . Check document on bottom of the page for details .

USER_INPUT : this channel contains a bitmask with state of rider BUTTONs . Check document on bottom of the page for details .

USER_OUTPUT : this channel contains a bitmask with state some ECU outputs . Check document on bottom of the page for details .

State channels

ENGINE_STATE : This one one of most important channels for diagnostics . It’s value contains infromations about actual engine syncronization state . If value is different than 782 ( 0x30E in hex ) You should check the reason why , because Your engine can run in protection an loose more than 10% of power . You can show a bit mask related to this channel on Your data analizer software , this will be very usefull . Check document on bottom of the page for details .

RBW_STATE : on motorbike equiped with with ride by wire system , this channel descrive the full diagnostic for this element . If You can show a bit mask related to this channel on Your data analizer software , this will be very usefull . Check document on bottom of the page for details .

DROPOFF_STATE : this is state of DROP OFF strategy . This can work using esternal TILT sensor , internal IMU or OPS ( oil pressure ) . It’s importnat to check value of this channel , to know your configration what sensor is using , and to know the reason why engine switched off . You can show a bit mask related to this channel on Your data analizer software , this will be very usefull . Check document on bottom of the page for details .

ENG_FUNCTION : here You can see what engine strategies are active . You can show a bit mask related to this channel on Your data analizer software , this will be very usefull . Check document on bottom of the page for details .

STR_FUNCTION : here You can see what vehcile dynamics strategies are active . You can show a bit mask related to this channel on Your data analizer software , this will be very usefull . Check document on bottom of the page for details .

Diagnostic channels

VREF_1 : Power supply feedback for main engine sensors . It’s value should be very closed to 5.0 Volt ( just few milli volt far ) , In case one or more sensors fails , You should ever check it , because of ofter one sensor broken in short circuit have effect on other .

VREF_2 : like for VREF_1 but for auxiliry sensors , not strictly related to engine .

SENSORS_DIAG : this is one of most important channel, because of this is the main source to know if some sensors are in fail state . Please check details on ducument on bottom of the page . If You can show a bit mask related to this channel on Your data analizer software , this will be very usefull .

ACTUATORS_DIAG : this is one of most important channel, because of this is the main source to know if some actuators are in fail state . Please check details on ducument on bottom of the page . If You can show a bit mask related to this channel on Your data analizer software , this will be very usefull .

BOARD_TEMP : it’s the actual temperature of ECU . ECU is designed to work up to 125 Celsius , but under this conditions it’s life is reduced , and some components can enter in protection mode . Optimal value is under 70 Celsius .

BOARD_TIME : you can use this channel to know the time ellapsed from ECU switch on . If You think , You can use it to know if there is a missing power supply that is cause of an issue .

ENG_REVOLUTIONS : this is a counter for engine revolution . You can use it to understand is ECU loose the syncronization for a while , for example because of crank shaft pickup sensor fails .